As Vice President of the Equipment Segment at the American Rental Association (ARA), Josh Nickell has seen it all when it comes to equipment rental trends, challenges, and success stories. Even with this depth and breadth of experience, recent rental equipment shortages have created complexity within the market.

“It seems like things are starting to lighten up and get a lot better,” said Nickell. “But, it’s category-specific. If you need a 180-foot boom, for example, there are only so many of those that exist out there and they can be really hard to come by.”

Though some equipment categories are becoming more available, Nickell noted a difference in how manufacturers and dealers have handled equipment shortages in the past 36 months.

“We really started to see things get pretty tough in early 2021,” said Nickell. “I would have (ARA) members call with concerns about new equipment availability, and even request ARA to push manufacturers to produce more. Of course, they were building fleet as fast as possible under the circumstances.”

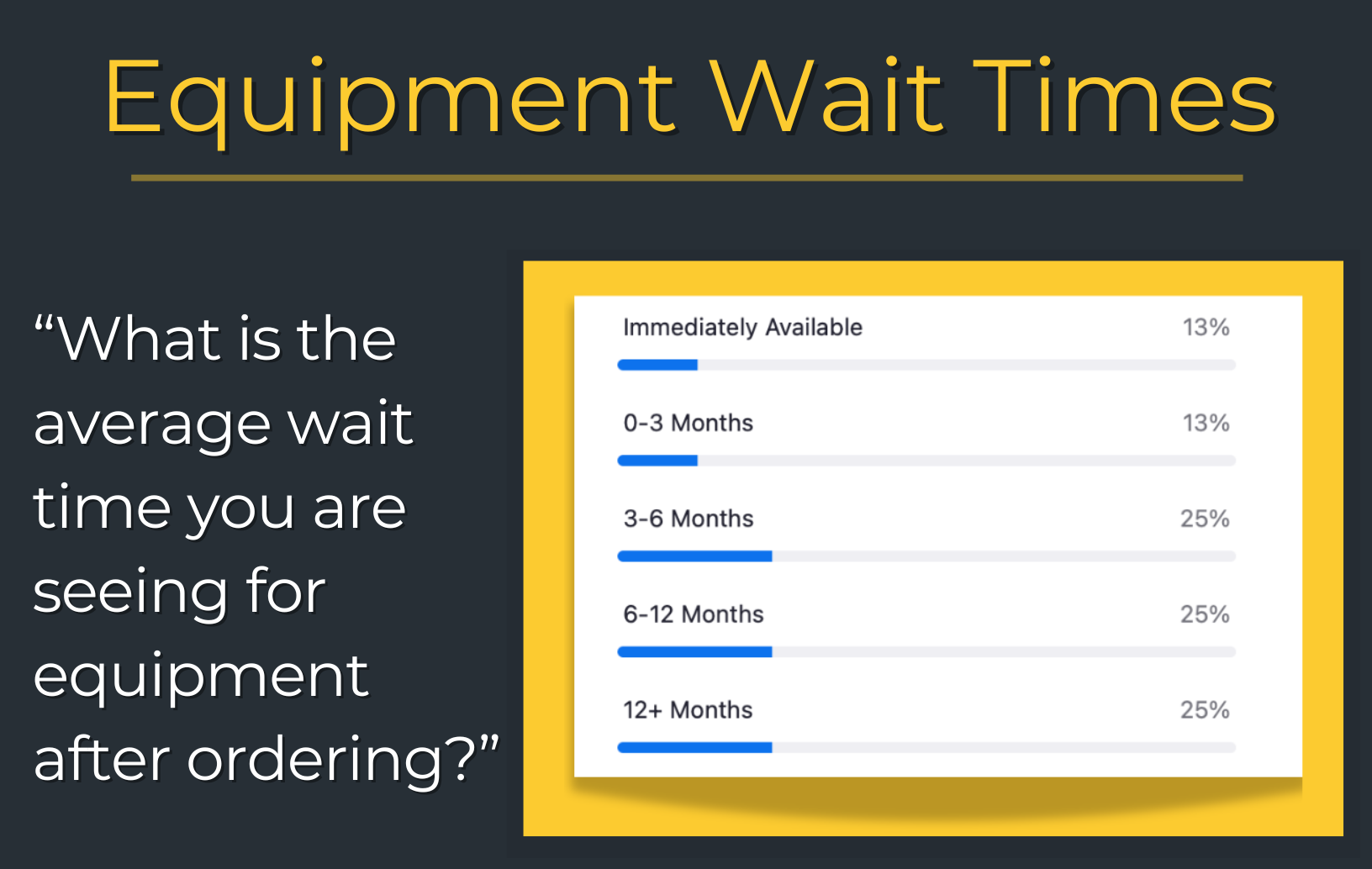

During a Texada Software webinar poll in September of 2023, attendees were asked about common wait times for rental equipment. In that poll, 75 percent reported wait times of over three months for equipment.

To handle the global shortages of parts and raw materials, equipment manufacturers have employed a variety of strategies, with some compounding the strain for rental businesses such as:

- Prioritizing larger (or smaller) rental business accounts

- Filling partial orders

- Focusing on higher profit machines or equipment

These strategies have created a challenging environment for equipment rental businesses and caused them to reconsider the state of their own fleets.

The State of Rental Fleets

As equipment rental businesses have faced difficulties acquiring new assets, both the value and age of their existing fleets have increased.

“We’ve been watching the average fleet age of rental companies go up and up for the last three years,” Nickell said. “The normal average fleet age is three and a half years. That means on average, you have new equipment in the fleet and seven years old equipment in the fleet. You’re selling it at an average of about seven years. We’ve seen that average move towards about four years, which means the oldest equipment is eight years old on average now.”

Similarly, as equipment outlasts its typical rental lifespan, the value of these older machines remains intact.

“We definitely have seen used equipment become incredibly valuable. It hit a high point about 12 months ago,” said Nickell. “There are a lot of things that you could buy, from trucks to excavators, where a unit that was a year old could be worth more than a new unit if it was available immediately. The problem was that you really needed it, especially if you were a rental company.”

To Sell or Not to Sell

Equipment rental houses have found themselves in an uncomfortable predicament. With valuable, yet aging, assets in their fleets, many have felt pressure to turn these machines into immediate profit, at the potential long-term expense of their business model.

“It was a painful proposition to own these assets. You knew you could turn a profit on it if you were a sales organization and willing to sell it,” said Nickell. “I think it made it really hard for many dealers with rental fleets because they were in a complicated position deciding whether to rent or sell. I think for your traditional rental company, they had to hang on to the equipment because they knew their customers needed it.”

With many rental organizations at record levels of time and dollar utilization and the return on investment of continuing to rent machines, most businesses have determined that it’s more profitable to continue supporting their customers over the short-term gain of outright selling their rental inventory.

The fact that it has been a relatively popular consideration, however, speaks to how deeply equipment shortages have affected the market.

Strategies for Success Amidst Equipment Shortages

Strategies that businesses have successfully employed to manage equipment shortages have included:

- Acquiring other rental companies with equipment inventory

- Focus on high quality preventative maintenance to increase the lifespan of aging equipment

- Make purchasing and fleet management decisions further in advance using analytics

- Pay attention to which categories and manufacturers have improving and reliable availability

Still others are simply waiting for manufacturers to fill critical equipment orders.

While the leveling out of equipment shortages should position most rental businesses for measurable gains in the near term, many are simultaneously grappling with a scarcity of skilled labor and technology adoption.

Find out how these trends affect businesses and a list of real-word strategies to manage them from industry experts in the latest full Rental Report from Texada Software.

December 13, 2024

December 13, 2024 3 minutes read

3 minutes read