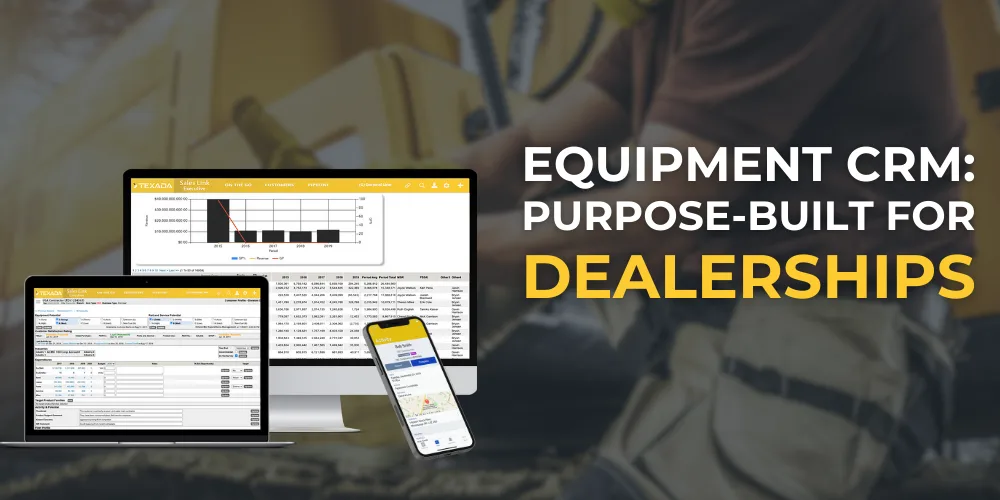

For the modern equipment dealership, every advantage has the potential to change the game. By identifying areas of opportunity within the business, organizations can optimize operations, increase technician productivity, and drive growth.

Time Consuming Activities

In addition to the financial implications and broader benefits associated with the optimization of heavy equipment technician productivity, it is essential to investigate practical strategies for identifying activities that consume significant time and potentially impede efficiency in the field.

“Over my many years of engagement with different dealers, there are a few major areas to consider when reflecting on what is keeping our technicians from selling revenue hours,” said Paul Phillips, an equipment dealer expert with 32 years in the industry. “I call these the Minute Thieves.”

The following is a partial list of time-consuming activities that can impact potential revenue.

Technician Productivity: 16 “Minute Thieves”

When it comes to non-revenue-generating activities, technicians take extra time to:

- Locate tools

- Look up and order parts

- Find relevant parts in the bay

- Access necessary shop cleaning items

- Perform cleaning tasks

- Research work order history

- Source service letter information

- Add parts and labor to work orders

- Obtain customer information

- Look for SOS results

- Manage condition monitoring alerts

- Purchase supplies

- Communicate with teams

- Attach inspections to work orders

- Review documents or media

- Schedule work

Phillips acknowledges that many of these areas of opportunity can be improved by automating processes and updating solutions.

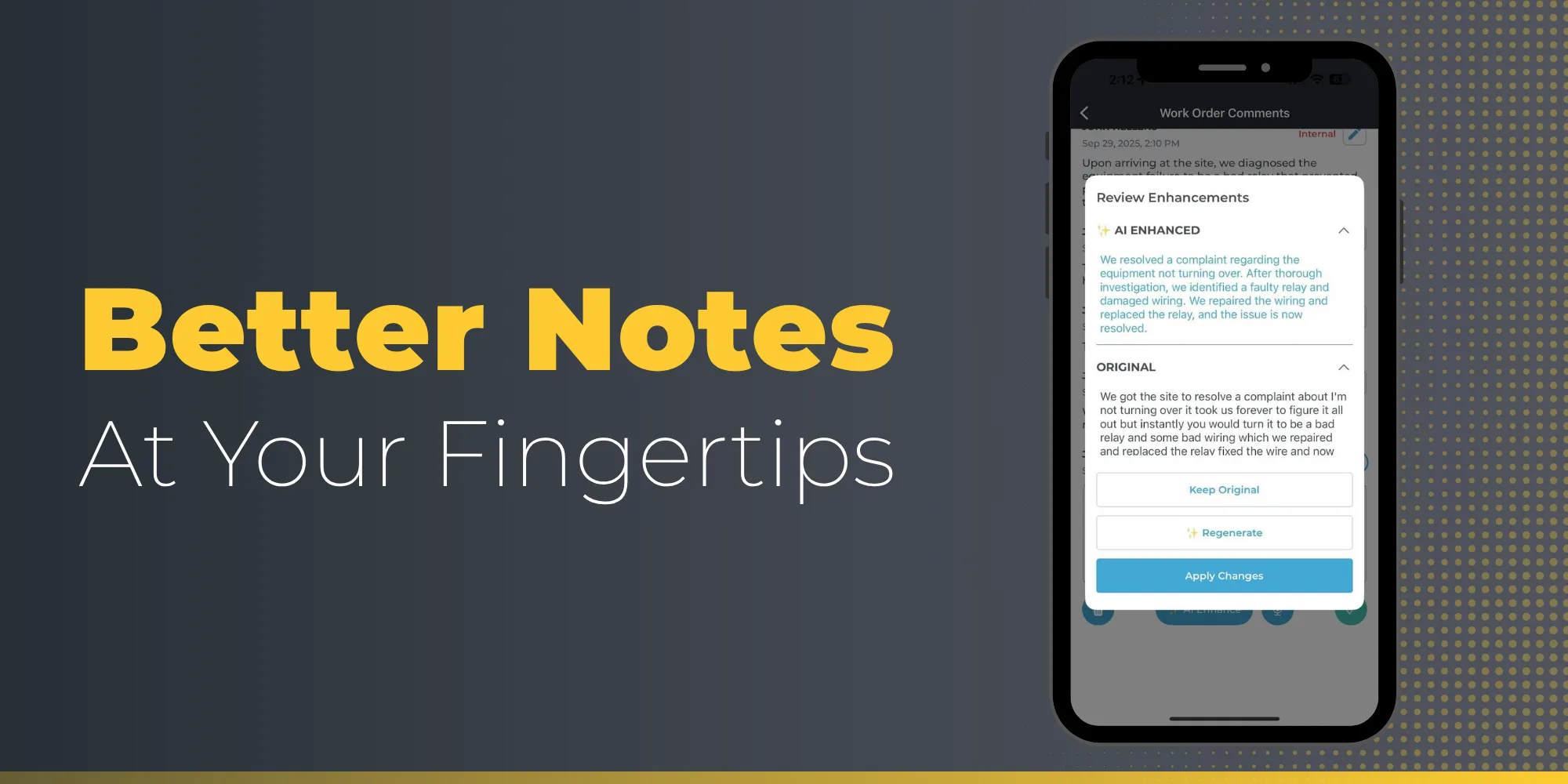

“When first getting a job, the technician needs to go into multiple screens just to find information,” said Phillips “Adding labor to a work order sounds simple, but there are still dealerships out there with a pretty manual process.”

Faster, more seamless communication can also streamline operations.

“Communicating internally could be electronic or it could be in person,” said Phillips. “Technicians communicate internally with supervisors, leads, technical communicators, or other individuals to pass information or share something with them that is necessary to complete the job.”

Adding notes, document access, and other communications capabilities can equip teams for success.

“For example, with Texada ServiceLink, you can look at the full work order history for a particular piece of equipment. You can look up the invoice details, view any warranty information, internal communication, and more.”

By focusing on the 16 areas of opportunity, organizations can begin to reduce non-revenue-generating tasks and boost technician productivity.

“A lot of these tasks take just a few minutes,” Phillips said. “Hopefully we can all look at this list and identify a lot of familiar ‘minute thieves’ that better solutions can eliminate.”

Access the complete Maximize Technician Productivity White Paper to learn more about Minute Thieves and get the five steps to supercharge technician productivity today.