Heavy equipment inspection is a regular, routine process that ensures your fleet is compliant. If executed properly, it can save you from a ton of headaches down the road in both monetary and process execution aspects.

Why regular asset inspections are critical to your heavy equipment lifespan

The list of benefits of proper and regular inspection is long, but above everything else, the safety of your workers is the most important. Some other benefits include the following:

- Save money– According to Farm Industry News, breakdowns due to downtime cost around $1,400 a day.

- Lower risk of workplace injuries– Restaffing is costly, both from a monetary perspective and a cost perspective. According to CAT, it costs around $4,129 to hire a new employee.

- Increase productivity– – Once you get into the flow of regular inspections, they’ll become quicker and easier to complete. Plus, you’ll be ensuring your equipment has as little downtime as possible.

- Lower repair cots– Regular small maintenance work can save you from having to purchase a replacement. We don’t have to tell you how expensive buying a new piece of equipment can be!

- Improve equipment availability

How can you see the equipment fleet through the eyes of an expert?

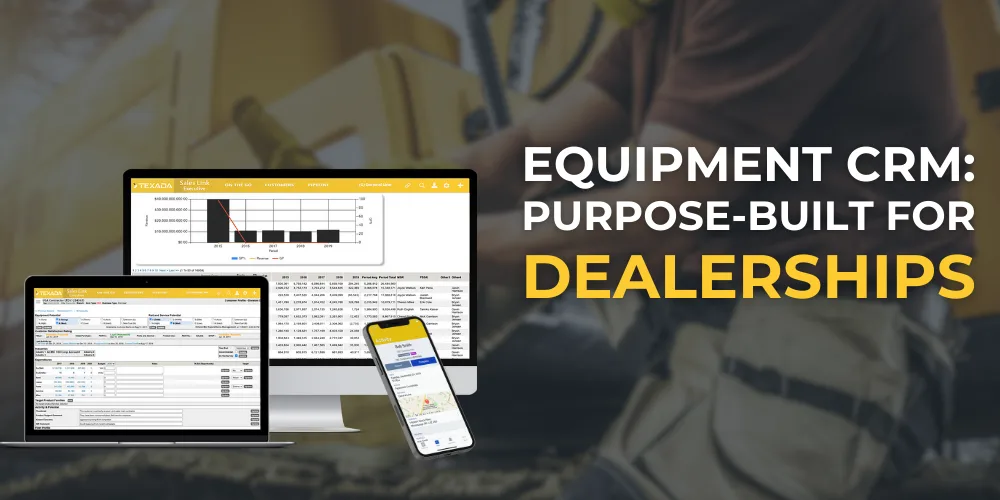

The Guided Damage System, which can be accessed through Texada Inspections, turns your field workers into heavy equipment inspection experts! This solution provides a step-by-step process for all inspection aspects, complete with photo verification, pictures of all inspection aspects, checklists and pictograms. They can check for leaks, broken, loose parts, excessively worn parts or any other potential problem areas – all personalized to your needs while still following international standards. The collected data is instantly added to the machine’s record (including any data from telematics), where the condition of the asset is analyzed. Afterwards, further steps will be recommended as needed!

Don’t wait until your equipment breaks down. By taking up preventative measures, you can save yourself money, time and a whole lot of trouble in the long run.

Texada Inspections is armed with powerful guided detection and asset condition assessment tools that can not only help with routine inspection but can also be tailored to fit your workflow. Interested?