Maintenance isn’t just a backend task; it’s the backbone of uptime, profitability, and customer trust. But too often, outdated tools and manual processes get in the way, turning routine service into a logistical headache. If you’re struggling with maintenance delays, miscommunication, or rising costs, you’re not alone. The answer? Equipment maintenance software.

This blog breaks down the top 10 challenges rental businesses face, and how the right equipment maintenance software can help you solve them.

1. Losing Track of Service History

If your maintenance records live in spreadsheets or scattered notes, things slip through the cracks. Inspections get missed. Repairs get repeated. A centralized tracking system keeps a complete history of every asset so you know exactly what’s been done and what’s due.

2. Maintenance Gets Benched

When rental demand is high, service often takes a backseat. That leads to breakdowns and costly delays. Software that automates scheduling makes it easy to prioritize maintenance without sidelining your fleet unnecessarily.

3. Unable to Locate Assets & Track Condition

If you’re walking the yard or making calls just to find out where equipment is or whether it’s ready, you’re wasting time. Real-time equipment tracking shows you location, status, and readiness all in one place.

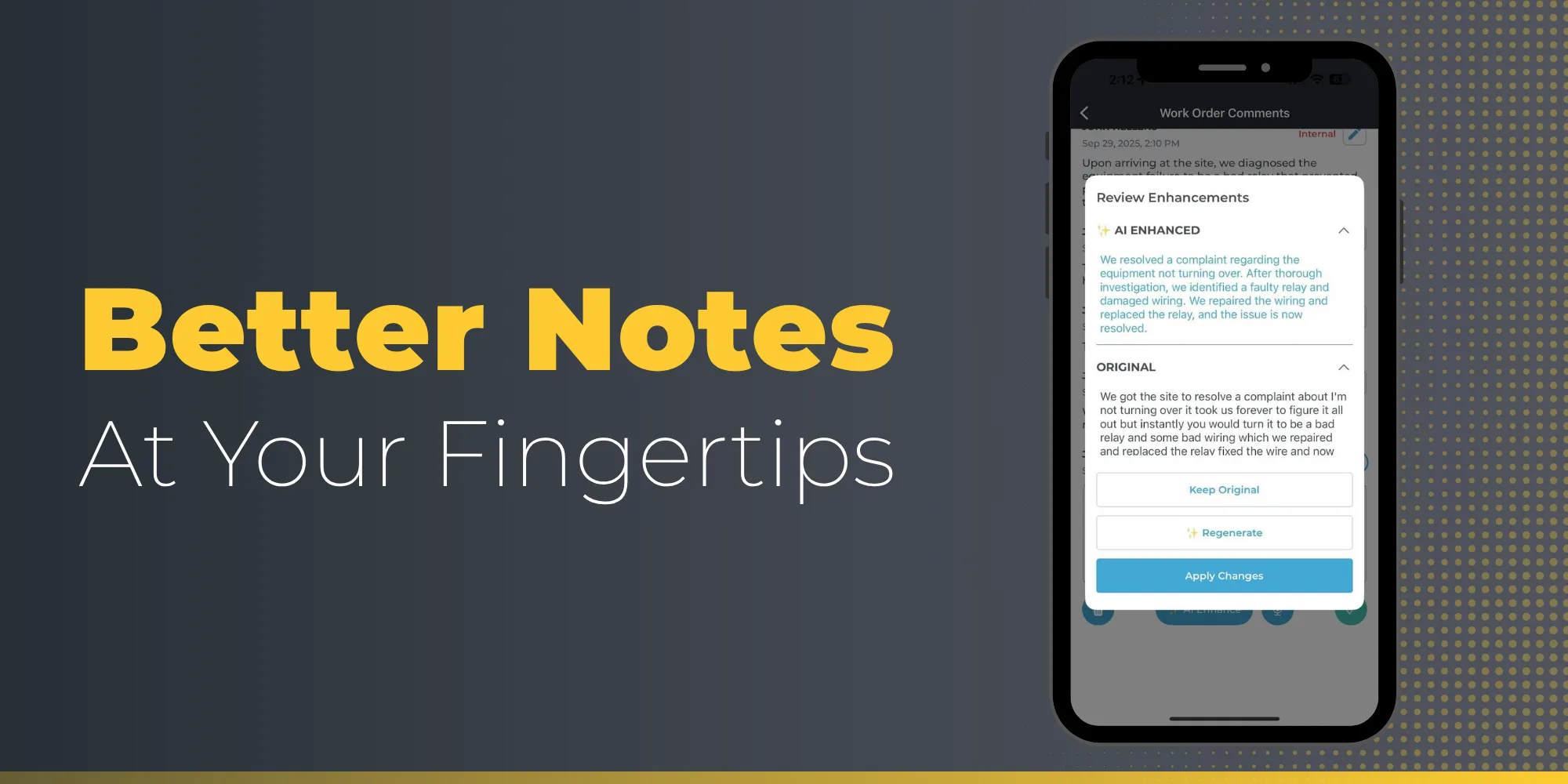

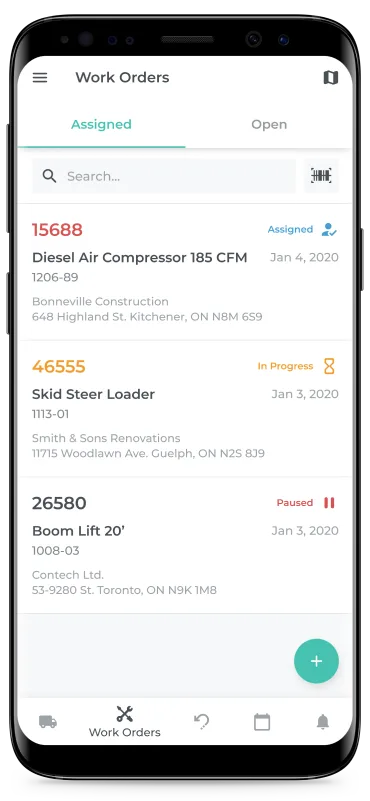

4. Work Orders Get Lost or Delayed

Paper-based or siloed systems create confusion about who’s doing what, when. Digital work order software simplifies task assignments, tracks progress, and keeps teams aligned, ensuring nothing is missed.

5. Inventory Blind Spots

You can’t complete repairs without the right parts. Equipment maintenance software that connects to your inventory system ensures parts are available when needed, cutting delays and avoiding rushed reorders.

6. No Analytics to Guide Strategy

Are your assets costing more than they’re worth? Are certain models breaking down more often? Without reporting tools, you’re left guessing. Analytics gives you a firm answer by helping you spot trends, budget smarter, and improve asset performance over time.

7. Problems Aren’t Caught Early Enough

Paper checklists and verbal updates can’t keep up with your fleet. Automated alerts and inspections help your team spot issues before they become expensive problems.

8. Your Tools Don’t Fit Your Processes

Every rental business works a little differently. If your system forces you to adapt to it, adoption suffers. The right software lets you customize dashboards, workflows, and checklists to match how your team actually works.

9. You’re Too Busy Growing

As your business grows, your systems should keep up. Scalable software supports your expanding fleet, workforce, and service needs, without retooling your entire operation. This flexibility also ensures you only pay for what you use.

10. You’re Paying For Software But Not Seeing Results

Software doesn’t have to be expensive to be powerful. A system that’s hard to use or doesn’t align with your needs won’t deliver value. The right solution saves you time and money by reducing downtime, extending asset life, and avoiding costly repairs. If you’re asking how to reduce equipment downtime, this is where to start.

Texada Gives Your Clarity, Control, and Confidence

At Texada, we understand that maintenance challenges don’t just disappear; they evolve. That’s why our equipment maintenance software is built to support the realities of your business: mobile workforces, tight schedules, and high customer expectations.

From digital work orders and integrated inventory tracking to real-time equipment insights and custom dashboards, Texada provides the tools to streamline operations and drive ROI.