Equipment dealerships and rental businesses need to meticulously maintain their fleets to ensure an uninterrupted flow of business prosperity. Understanding the basics of fleet management and inspection is not merely a matter of routine but a fundamental bedrock that ensures operational resilience and reliability.

This practice is about staying in compliance with regulatory standards, safeguarding the investment in your equipment, and guaranteeing customers’ ultimate satisfaction. Let’s delve into why establishing a stringent post-return maintenance protocol is paramount for the longevity and efficiency of your vehicular assets.

Schrödinger’s Bobcat: Is Your Fleet Dead or Alive?

Fans of the hit show The Big Bang Theory may have already heard of Schrödinger’s Cat. For those unfamiliar with the concept, Schrödinger’s Cat is a famous quantum mechanics theory in which a cat is placed into a box containing poisonous gas. While the box is sealed, the cat’s fate is uncertain, and it is considered to be both alive and dead. Only opening the box and observing the cat allows us to know its actual state.

So why on earth are we talking about a cat that may or may not have died in 1935? Well, you may be repeating this experiment in your rental business. When an asset is returned from the rental and put in the yard without an inspection, you create Schrödinger’s Bobcat.

The Importance of Immediate Post-Return Fleet Maintenance

Implementing thorough fleet maintenance and inspections immediately after equipment returns is a good practice and the cornerstone of responsible fleet management. Addressing the operational conditions of each piece of equipment right off the bat empowers a proactive stance on maintenance, which translates into multiple long-term benefits for the entire fleet.

As long as an asset sits in the yard uninspected, it is both dead and alive. Meaning that it is simultaneously in need of repair and ready to be rented again. Only the act of inspecting the equipment allows us to know its status.

If an asset is in need of repair when you need it to fulfill a rental order, and you are unaware of the damage, that is when the panic sets in. You need to scramble to get it fixed in time, or you have to re-rent another vendor’s equipment, or, possibly worst of all, you lose the sale. Now, you are quickly slashing away at your profits. You also introduce the risk of your customer renting directly from the re-rent vendor in the future, lowering customer retention rates. Do you see the snowball effect?

Addressing Minor Issues Before They Become Major

Minor issues can escalate into costly repairs if not identified and resolved swiftly. Immediate post-return maintenance checks ensure that small problems, like a worn belt or leaking fluid, are noticed and rectified before they can grow into larger, more complex ones. This proactive approach is crucial for maintaining the integrity and reliability of each equipment within the fleet.

Saving on Long-Term Costs Through Early Detection

Meanwhile, you are stuck paying to get the original asset repaired, even if it was a customer error that caused the damage, because it has been weeks since the asset was returned. Going back to the original customer who did the damage to the equipment and looking for them to pay up weeks later is not likely to work out.

Now imagine if you had just spent a few minutes looking over the asset when it was returned. A quick inspection to record the status of the equipment upon return could save you all these headaches. If there was damage, you could have immediately started the repair, billed the customer who caused the damage, and had the asset back in rent-able condition in time to fulfill the next rental order.

Early detection of potential problems can significantly save repair and parts replacement costs. By conducting immediate post-return inspections, fleet managers can avoid the financial impact of unexpected breakdowns and the premium charges often associated with expedited part shipments or emergency repairs.

Ensuring the Next Run Meets Safety Standards

Safety is non-negotiable in fleet operations. Immediate post-return inspections are essential to ensure the equipment complies with safety regulations and standards before hitting the road again. This systematic check of the fleet’s mechanical and safety features not only helps to protect drivers and other road users but also safeguards the company against non-compliance fines and reputational damage.

- Effective management of wear and tear.

- Identification of irregularities that could hinder equipment’s performance.

- Verification of essential safety components such as brakes, tires, and lights.

Pro Tip: Conduct immediate post-return inspections to swiftly identify and address minor issues, ensuring equipment safety, compliance, and readiness for the next rental while preventing costly repairs and operational disruptions.

Cost Savings Through Preventive Maintenance

Preventive maintenance is one significant area often overlooked when managing a fleet. Yet, this aspect is critical in ensuring short-term and long-term cost savings. By avoiding potential mechanical issues, fleet managers can notably decrease the frequency and severity of costly equipment repairs.

Cutting Down Expenses with Regular Fleet Servicing

Consistent equipment servicing isn’t merely a recommendation; it’s a financial strategy. Regular maintenance helps identify minor problems before they escalate into expensive failures. Keeping engines properly tuned, tyres at the correct pressures, and components lubricated considerably reduces the risk of sudden and costly breakdowns. This proactivity directly saves potential towing costs, part replacements, and labor charges associated with emergency repairs.

Reducing the Likelihood of Expensive Repairs

Unexpected repairs can severely impact a company’s operating budget. Regular fleet inspection and maintenance reduce the likelihood of facing such unwelcome surprises. A well-maintained fleet is less likely to encounter serious mechanical issues that could lead to significant downtime and hefty repair bills. Preventive maintenance is the cornerstone of a strategy prioritizing financial foresight over-reactive spending. By investing in routine check-ups, companies can extend the life of their equipment and avoid the high costs associated with major repairs or early equipment replacement.

- Detailed service records ensure that no aspect of fleet maintenance is neglected.

- Predictive maintenance techniques can be employed to forecast when equipment parts might fail, allowing for planned interventions that are less disruptive and more cost-effective.

- Budgeting for regular maintenance rather than unexpected repairs helps stabilize financial planning and contributes to better fleet cost management overall.

Pro Tip: Implement regular preventive maintenance to reduce costly breakdowns, extend equipment lifespan, and ensure budget stability, leveraging detailed service records and predictive maintenance techniques for optimal fleet management.

Decreasing Equipment Downtime

Any fleet manager must minimize the time an equipment is out of service. An effective post-return maintenance and inspection routine can significantly reduce the time the equipment is unavailable due to repairs. This proactive approach allows for more consistent operations and reduces disruptions from unexpected issues.

By swiftly resolving problems post-return, fleet operators ensure that the fleet is always in operational readiness. When issues are detected early through thorough inspections, repairs can be scheduled during off-hours, keeping the fleet running without costly interruptions. This immediacy in addressing issues can lead to fewer long-term complications and sustain the fleet’s operational efficiency.

- Reducing downtime means more efficient use of equipment and personnel, which translates into higher productivity and profitability for the business.

- Maintaining operational readiness is a matter of efficiency and a competitive advantage in the fast-paced logistics environment.

Pro Tip: Minimize equipment downtime by conducting timely post-return inspections and maintenance and scheduling repairs during off-hours to ensure continuous operational readiness, boost productivity, and maintain a competitive edge.

Best Practices for Post-Return Inspections

An asset’s return to the equipment yard is one of the best moments for an inspection. Fleet managers must adhere to established best practices to maintain the highest safety, compliance, and performance standards. These post-return inspections are crucial for several reasons: they ensure the fleet remains in optimal operational condition, minimize breakdowns, and uphold the safety of subsequent users.

Established Best Practices for Inspecting Equipment Upon Return

- Detailed Checklist: Utilize a thorough inspection checklist tailored to each equipment type to ensure no component is overlooked.

- Systematic Approach: Inspect the fleet systematically, from the engine and transmission to brakes, tires, and electronics.

- Documentation: Document findings meticulously to track equipment condition over time and make informed decisions on repairs and maintenance.

- Timely Repairs: Address identified issues promptly to keep your fleet in ready-to-use condition and prevent minor problems from escalating.

Critical Elements to Inspect Consistently

Fleet managers should focus on inspecting critical equipment components that bear the brunt of wear and tear. These elements impact performance and play a significant role in ensuring road safety.

- Brake System: Check for worn pads, fluid levels, and proper brake function.

- Tires: Assess tire pressure and tread depth and look for signs of damage or unusual wear.

- Lights and Signals: Ensure headlights, brake lights, turn signals, and emergency flashers are operational.

- Engine Compartment: Evaluate the engine for leaks, oil level, and the condition of belts and hoses.

Actionable Steps for an Efficient Post-Return Inspection Routine

- Train Staff: Educate your personnel on inspection procedures and the importance of thoroughness.

- Regular Schedule: Conduct inspections consistently after each piece of equipment’s return to the spot and address issues immediately.

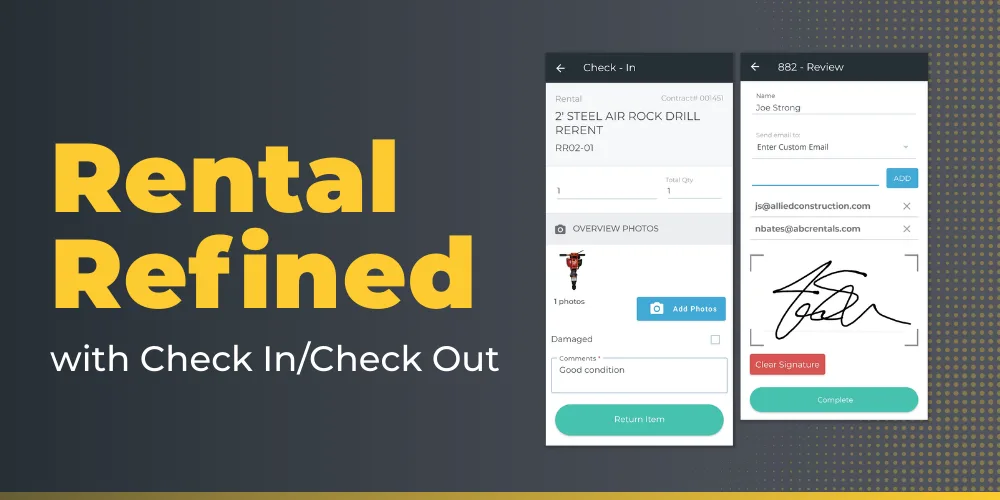

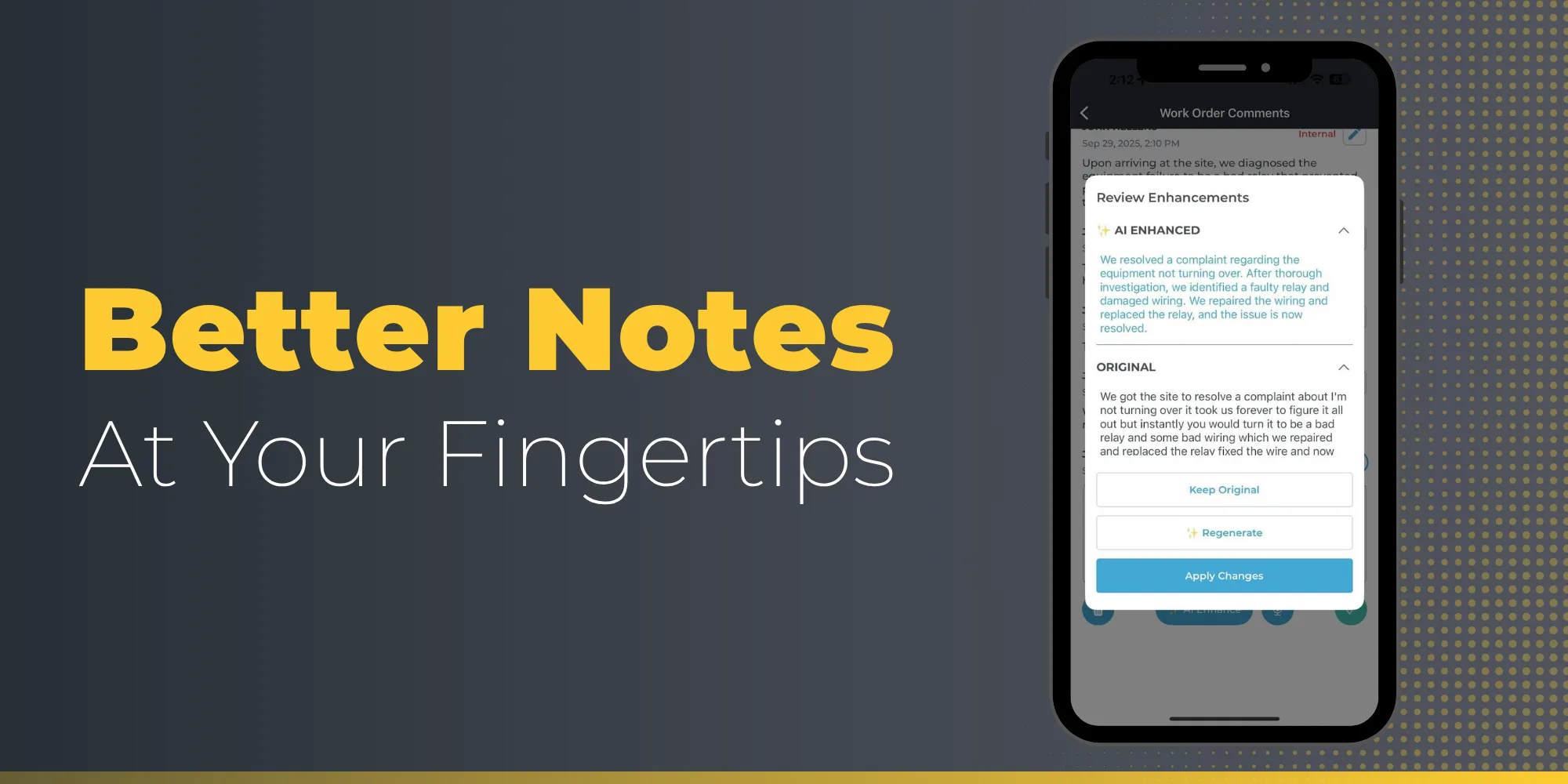

- Use of Technology: Implement fleet management software to assist with scheduling, reminders, and record-keeping.

- Feedback Loop: Encourage drivers to report any issues they notice during their use, creating a proactive maintenance culture.

Using Inspection Data to Inform Fleet Maintenance Decisions

Data collected from post-return inspections is invaluable in informing fleet maintenance decisions. The information gleaned helps managers to:

- Track recurring issues and identify systemic problems.

- Adjust maintenance schedules based on real-world fleet usage and condition.

- Allocate resources more efficiently, focusing on areas that need the most attention.

- Improve the fleet’s overall reliability and readiness.

By taking a data-driven approach, fleet managers can elevate their maintenance protocols, aligning them with the wider best practices of fleet management.

Technology Integration in Fleet Maintenance

Keeping pace with technological advancements is crucial in the evolution of fleet maintenance. Today, technology integration has become indispensable for efficient and comprehensive inspections and proactive maintenance of fleets. By leveraging the latest tools, solutions, and information systems, companies can ensure their fleets operate at peak efficiency, reducing the risks associated with delayed maintenance and unscheduled repairs.

Modern Tools and Information Systems

Modern fleet maintenance involves more than just manual inspections and reactive repairs. Information systems and solutions designed specifically for fleet management utilize live data to track fleet performance, schedule maintenance, and record inspection outcomes. These systems ensure accurate and up-to-date tracking of each equipment’s condition and facilitate timely interventions.

The Benefits of Advanced Diagnostics and Telematics

Advanced diagnostic tools and telematics systems offer many benefits that traditional maintenance methods cannot match. With these technologies, it is possible to:

- Predict potential issues before they escalate into costly repairs.

- Maintain detailed records of fleet health and schedule predictive maintenance efficiently.

- Gain real-time insights into fleet performance and usage patterns, which help in making informed maintenance decisions.

- Ensure that maintenance staff can quickly identify and address mechanical problems more precisely.

Integrating these technological solutions into fleet maintenance strategies improves operational reliability and overall fleet management effectiveness.

Pro Tip: Integrate advanced diagnostics and telematics into your fleet maintenance strategy to predict issues early, maintain detailed health records, and gain real-time performance insights, ensuring peak efficiency and reducing repair risks.

Essential Checklist for Post-Return Inspections and Quality Control Measures

Checklist for Post-Return Inspections

| Inspection

Point |

Details |

| Engine | Check for leaks, unusual noises, or any signs of wear and tear. |

| Brakes | Inspect for proper operation, condition of pads, and fluid levels. |

| Tires | Evaluate tread depth and wear patterns and ensure proper inflation. |

| Lights and Signals | Ensure all headlights, brake lights, turn signals, and hazard lights function. |

| Oil and Fluid Levels | Check and top up engine oil, coolant, power steering, brake, and transmission fluids if necessary. |

| Windshield Wipers | Assess wiper blades for damage and ensure the wiper fluid reservoir is full. |

| Battery | Test battery life and clean terminals if needed. |

| Cargo Area | Inspect for cleanliness and ensure no left-behind items or damage occurred during the usage. |

| Exterior | Check for any new damage to the bodywork, including dents, scratches, or rust. |

| Interior | Verify the cleanliness and functionality of all interior components. |

Quality Control Measures for Reliable Inspections

| Quality Control Measure | Details |

| Standardize the inspection process | Ensure consistency across your fleet. |

| Utilize technology | Log and track inspection results for each piece of equipment. |

| Train maintenance personnel | Emphasize the importance of thorough inspections and identifying potential issues. |

| Regularly review and update the checklist | Address emerging issues or changes in compliance requirements. |

| Ensure timely follow-up | Prevent future breakdowns and malfunctions by addressing identified problems promptly. |

| Create a culture of accountability | Encourage technicians and maintenance staff to take ownership of the fleet’s condition. |

The Compelling ROI of Effective Fleet Maintenance Programs

Regular fleet maintenance and inspection is a strategic investment that yields dividends. Maintaining a fleet that is safe and compliant with regulations is not simply a box to be checked. It directly translates to protecting the company’s assets and capital.

While the upfront costs of establishing a comprehensive fleet maintenance program may seem daunting, the long-term savings are undeniable. Companies that invest in the health of their fleet can expect:

- A more reliable and efficient fleet that ensures uninterrupted service and customer satisfaction.

- Lower total cost of ownership due to fewer emergency repairs and better resale values for well-maintained equipment.

- Stronger compliance posture, safeguarding against regulatory changes and scrutiny.

At Texada, we understand that regular fleet inspection can still be a time-sink. However, our inventory management and intelligent damage detection software streamline the entire process, making fleet management simpler and more intuitive. Want to learn more about how Texada’s software solutions can optimize how you manage your fleet?

[Speak with an expert]

Key Takeaways

- Immediate post-return inspections help identify and address minor issues before they escalate into costly repairs, ensuring fleets are always in optimal condition and ready for the next rental.

- Early problem identification reduces the financial impact of unexpected breakdowns and expensive emergency repairs while enabling timely billing for customer-caused damages.

- Regular and thorough inspections guarantee that the equipment meets safety standards and regulatory compliance, protecting drivers and the company from legal and financial repercussions.

- Consistent maintenance and detailed service records extend equipment life and enhance resale value, demonstrating well-maintained assets to potential buyers and ensuring long-term financial returns.