The heavy equipment industry powers construction, infrastructure, and agriculture across the globe. But if you’re in the thick of it, you know this world comes with big challenges — from rising costs to skilled labor shortages to growing customer demands.

Good news? With the right equipment rental software or dealer software, you can tackle these headwinds head-on and even turn them into opportunities. Let’s break down the top challenges shaking up the heavy equipment space — and how smart solutions help you come out ahead.

1. Skilled Labor Shortage: Building a Stronger Workforce

The challenge: Skilled operators and technicians are retiring, and younger workers aren’t filling the gap fast enough. This labor shortage is slowing projects and driving up costs.

Why it matters:

- Lower workforce productivity

- Increased training costs

- Tougher competition for top talent

How Software Helps

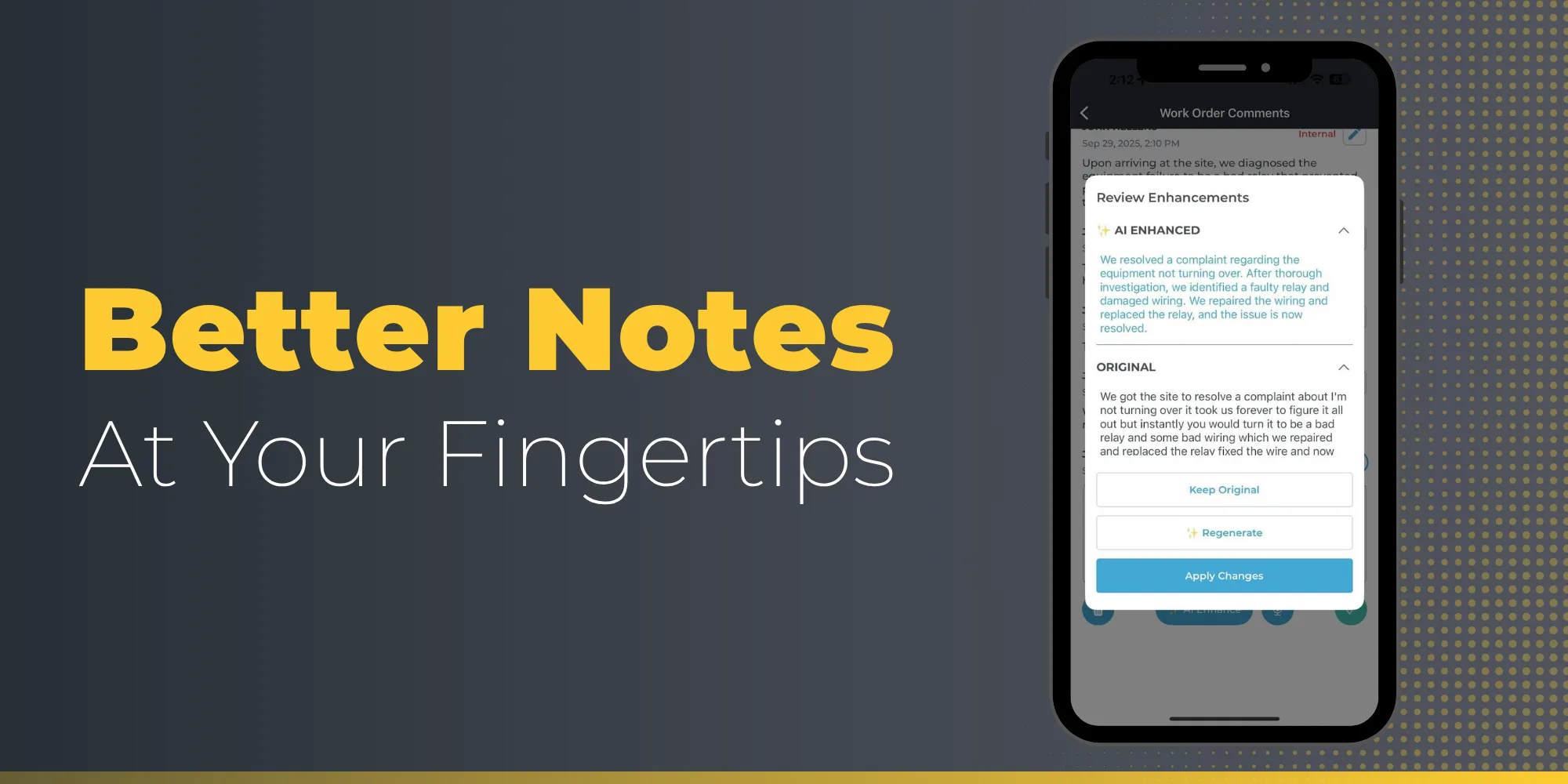

Modern rental management solutions help streamline onboarding, track apprenticeship progress, and simplify workflows. With digital inspections, guided checklists, and integrated systems, even junior staff can work confidently and efficiently. Plus, training modules keep your workforce adaptable as construction equipment technology evolves.

2. High Equipment Costs: Maximizing Your Investment

The challenge: Heavy machinery is expensive to buy, operate, and maintain. Poor equipment management can sink profitability.

Why it matters:

- Unpredictable repair and replacement costs

- Low equipment utilization rates

- Strained cash flow

How Software Helps

With robust fleet management tools, you get real-time visibility into usage, performance, and maintenance schedules. Predictive maintenance reduces downtime, while lifecycle management features help you decide when to repair, replace, or sell assets — ensuring you get the most out of every machine.

3. Supply Chain Disruptions: Staying Resilient

The challenge: From global shortages, tariffs, shipping delays, and more, the construction supply chain has become unpredictable.

Why it matters:

- Project delays and cost overruns

- Idle equipment and labor

- Frustrated customers

How Software Helps

Advanced inventory management systems let you monitor parts availability, track supplier lead times, and automate reordering. Built-in forecasting tools help you navigate disruptions and keep projects moving smoothly, even when markets are volatile.

4. Equipment Theft & Security Risks: Protecting Your Assets

The challenge: Equipment theft costs the heavy equipment industry millions every year.

Why it matters:

- Lost revenue and productivity

- Higher insurance premiums

- Project interruptions

How Software Helps

Integrated tools like GPS tracking lets you monitor and secure your fleet in real time. Combined with a strong risk management plan, these tools help you proactively safeguard your assets.

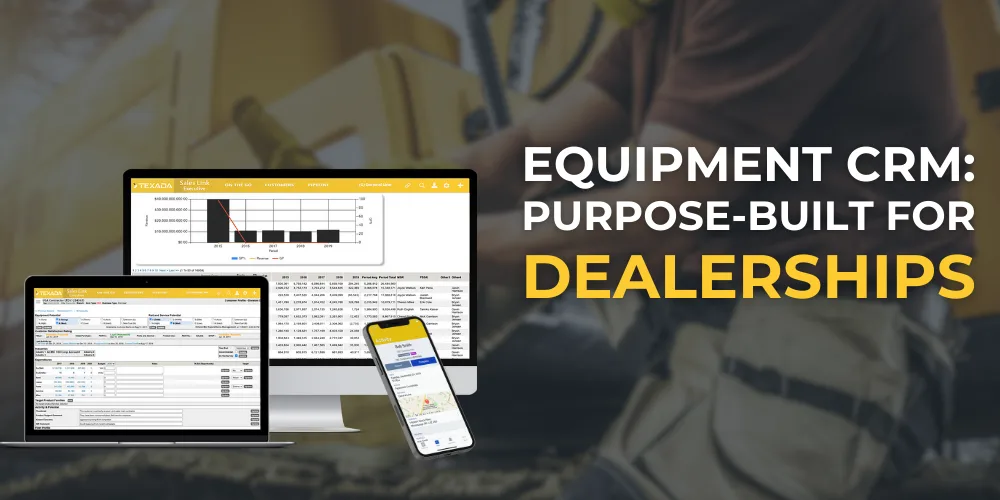

5. Rising Customer Expectations: Competing in a Digital Marketplace

The challenge: Today’s rental and dealership customers want fast, convenient, online service. Competitors are no longer just across town — they’re online, offering streamlined digital experiences.

Why it matters:

- Increased customer churn

- Growing pressure on margins

- Barriers to scaling operations

How Software Helps

Online booking platforms and customer portals let your clients manage rentals, view contracts, and pay invoices anytime, anywhere. This improves customer experience, frees up your team, and gives you an edge in a competitive market.

Equip Your Business for Success

The heavy equipment industry isn’t for the faint of heart — but with the right tools, you can turn its biggest challenges into opportunities for growth. By embracing modern software solutions, you’ll boost efficiency, protect your bottom line, and deliver exceptional service.

Ready to explore how technology can help your business rise above these challenges?